DESIGNING AND MANUFACTURING PROCESS

SIPEUROPE’s certified SE-SIP construction system is manufactured under controlled and regulated factory conditions. The manufacturing process has several stages and usually takes from 4 to 8 weeks.

SIPEUROPE’s certified SE-SIP construction system is manufactured under controlled and regulated factory conditions. The manufacturing process has several stages and usually takes from 4 to 8 weeks.

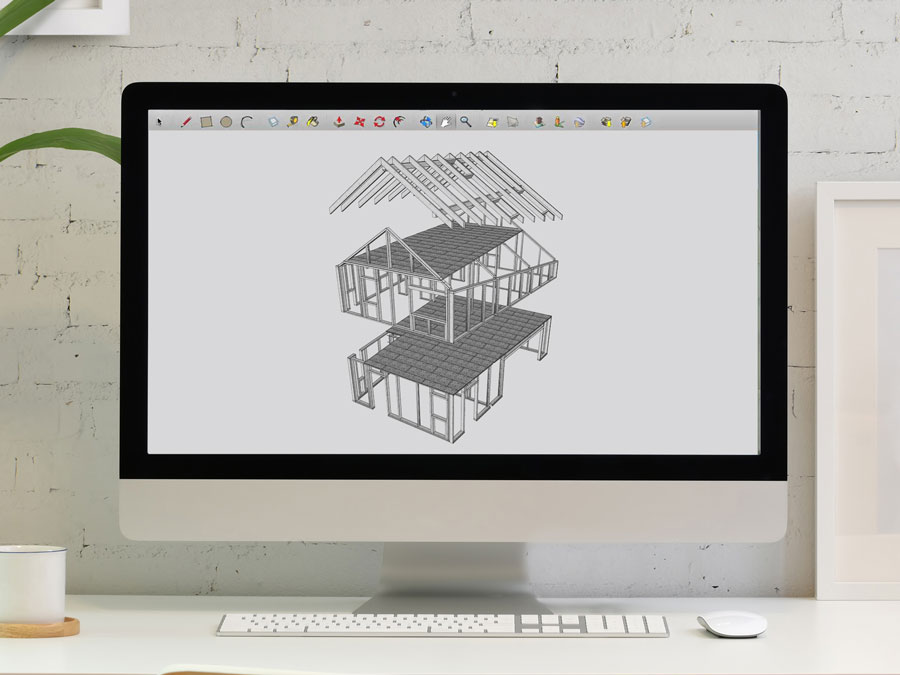

Technical, assembly and manufacturing documentation is being prepared in the design phase. SIPEUROPE uses state-of-the-art design technologies for processing technical and manufacturing plans that are also compatible with BIM (Building Information Modeling). This technology significantly reduces the time of designing and drafting. In the design phase, project documentation is being communicated and approved. Our professional team of engineers is ready to provide any consulting in the design process, project finalization, as well as structural assessment of buildings.

After completion of the design and approval of technical documents comes the optimization phase. SIPEUROPE manufactures custom-made panels that are marked according to the project documentation. At this stage, the cutting plans are optimized.

Our customers will therefore receive pre-prepared and marked panels without the need for additional shaping. For this reason, the construction process is very fast, precise and customers do not produce construction waste from the panels.

The manufacturing process takes place in controlled and strictly regulated factory conditions.

Factory conditions and machine technology ensure enormous speed, precision and efficiency of manufacturing of the SE-SIP construction system. The sandwich panel is formed by adhesive bonding of the insulating core between two 15mm OSB TOP 4 boards. Then the panel hardens and matures in a hydraulic press. After the hardening, the panels are formatted and marked. Once the contract has been completed, the panels, as well as all other materials necessary for the construction, are loaded on trucks that will take them to the construction site.

We provide our customers with full technical support as well as educational service. For the construction of the SE-SIP construction system, we offer certified training to construction companies and assembly groups throughout the EU.

SIPEUROPE offers a complete construction system, including all the necessary materials for the completion of a rough-in. For the customer, we provide comfortable construction management without unnecessary interruption due to subcontracting.

Interested in our activity and want to learn more?

Contact us